Aquatherm Valve Applications

201304A – AQTTB

Date Issued: 18 April 2013

Aquatherm offers a variety of valves in our catalog. These valves range in offering between the screw-down stop globe valve, concealed valves, inclined globe valves and ball valves.

This document is an attempt to identify the valve offerings and their different applications.

Globe Valves

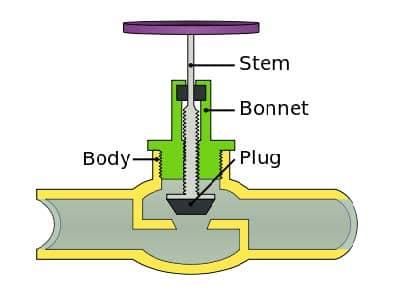

Globe valves are named for their spherical body shape with the two halves of the body being separated by a baffle (see Figure 1) consisting of a movable disc-type element and a stationary seat. Aquatherm’s globe valves do not have a spherical body.

Figure 1: Globe Valve

Globe valves, due to their internal design, are used mainly for flow control. They operate fairly efficiently in a partially open position to throttle or control the flow rate of liquids. They are used to control flow rates when mixing fluids or in batching operations where fluids may need to be continuously adjusted. Globe valves can be operated manually or by an actuator.1

Advantages: Can be fast acting; Precise Control; Can be used in high-pressure systems.

Disadvantages: High head loss; Large opening for disk assembly; low coefficient of flow; Not good for clean or sterile applications; Valve stem requires many turns to open or close.

Aquatherm offers globe valves in straight and inclined or “Y” globe versions.

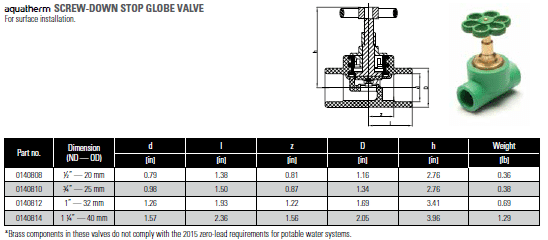

Figure 2: Straight Globe Valve

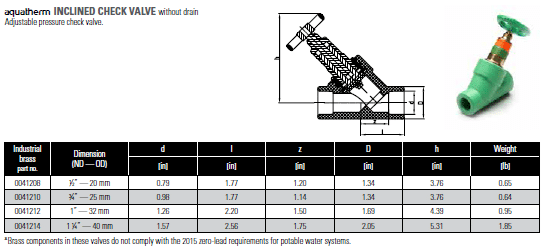

Figure 3: Y-Pattern Globe valve, Inclined Check valve. This valve has a spring inside to keep the plug on the seat, thus preventing revers flow through the valve.

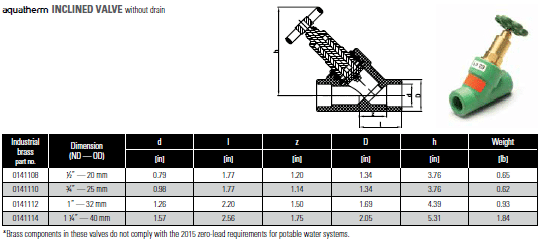

Figure 4: Y-Pattern Globe Valve

Y-body design valves, also known as crossflow globe valves, derive linear action from the incline between the axis of the inlet and the outlet ports. This design reduces the high pressure drop inherent in globe valves. The seat and stem are at a 45° angle with the media flow, for a straighter flow path at full opening. The Y-design also keeps the stem, bonnet and packing in a relatively pressure resistant envelope. This valve design is well suited for high pressures and other severe services.2

Figure 5: Y-Body Globe Valve

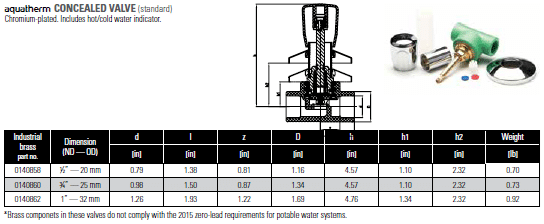

Concealed Valves

Aquatherm also offers a line of concealed valves. These valves are offered in ½”, ¾” and 1” sizes. They are globe valves that are mainly used for control at fixtures such as lavatories, sinks, and water closets. These valves are available in short stem lengths and longer stem lengths from 2” to 4” in length. They are also available with chrome plated valve handles in tamper proof designs.

Ball Valves

A ball valve is a valve with a spherical disc, the part of the valve which controls the flow through it. The sphere has a hole, or port, through the middle so that when the port is in line with both ends of the valve, flow will occur. When the valve is closed, the hole is perpendicular to the ends of the valve, and flow is blocked. The handle or lever will be in line with the port position letting you “see” the valve’s position. The ball valve, along with the butterfly valve and plug valve, are part of the family of quarter turn valves.

Ball valves are durable and usually work to achieve perfect shutoff even after years of disuse. They are therefore an excellent choice for shutoff applications (and are often preferred to globe valves and gate valves for this purpose). They do not offer the fine control that may be necessary in throttling applications but are sometimes used for this purpose.

Ball valves are used extensively in industrial, commercial, and residential applications because they are very versatile, long-lived and easy to operate, supporting pressures up to Aquatherm piping’s maximum pressures and temperatures. See the piping technical data. Sizes typically range from ½” to 6” (20 mm – 160 mm). Some designs may be field repaired or modified.3

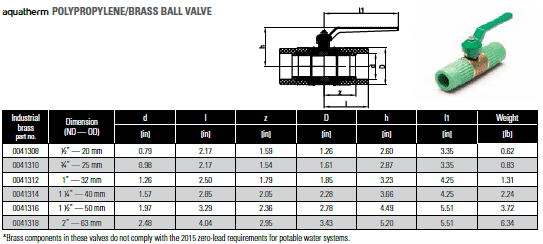

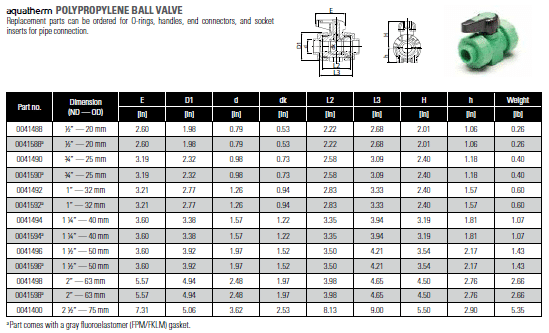

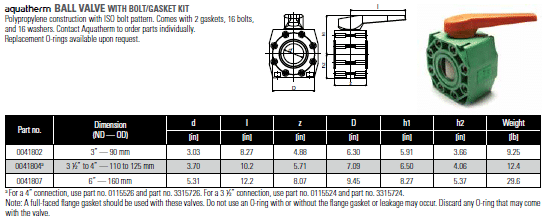

Aquatherm offers a line of ball valves from ½” to 6” in brass/polypropylene and polypropylene. The following figures are taken from the Parts Guide showing the various ball valves available. All of the ball valves offered by Aquatherm are full-port ball valves, meaning that the port or opening in the ball is the full size of the pipe in which the valves is being placed.

Ball valves may be operated manually or by use of an actuator.

Figure 6: Brass Ball Valve with PP Connections

The maximum rated temperature and pressure of the ball valves shown above are based on the piping connected to the valve, which can be found in the technical manual for the pipe and fittings (permissible Working Pressure tables).

Figure 7: Polypropylene Ball Valve with Union Type Connections

The polypropylene valve shown above is made for insertion into a pipeline with union-type connections. It can be removed for repair or replacement without cutting the valve out of the line and re-welding the piping.

Figure 8: Large Ball Valve 3″ – 6″

Note that the ball valve shown above requires the use of two flange adapters and flange rings. The required bolts are noted in the Parts Guide cut. Note also that the flange adapter rings must be metric ISO-based flanges/rings rather than ANSI rings. The Aquatherm Flange rings are machined to work with both ISO and ANSI up to 6” (160 mm).

Ball valves advantages and disadvantages:

Advantages: Quick on-off control; Durable and versatile; operate smoothly even after years of non-use; positive shut off.

Disadvantages: No fine control for throttling operations; Quick shut-off may produce water hammer.

Flow Coefficient

The flow coefficient of a device, such as a valve, is a relative measure of its efficiency at allowing fluid flow. It describes the relationship between the pressure drop across an orifice, valve or other assembly and the corresponding flow rate.

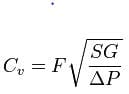

Mathematically the flow coefficient can be expressed as:

Where:

Cv = Flow coefficient or flow capacity rating of valve.

F = Rate of flow (US gallons per minute).

SG = Specific gravity of fluid (Water = 1).

ΔP = Pressure drop across valve (psi).

In more practical terms, the flow coefficient Cv is the volume (in US gallons) of water at 60°F that will flow per minute through a valve with a pressure drop of 1 psi across the valve.

The use of the flow coefficient offers a standard method of comparing valve capacities and sizing valves for specific applications that is widely accepted by industry.4

Sources:

- McGraw-Hill Science & Technology Dictionary: Globe Valves; McGraw-Hill Dictionary of Architecture & Construction: Globe Valves

- HIS Global Spec, https://www.globalspec.com/learnmore/flow_control_flow_transfer/valves/globe_valves, Globe Valve Information, How to Select Globe Valves

- https://www.valveman.com/butterfly-valve-or-a-ball-valve/

- https://www.valveman.com/what-is-a-cv/

Revisions:

- 3 Nov. 2021 – Updated and revised part numbers and offerings