COPPERWORKS DISTILLING COMPANY PICKS AQUATHERM FOR SIX-STORY PROCESS COOLING SYSTEM

aquatherm’s natural R-value, corrosion-resistance, longevity and sustainability contributed to the efficient and economical operation of their stills.

The Challenge

The distillery’s original copper piping system wasn't keeping the process cooling water chilled up to ownership’s expectations.

The Solution

aquatherm’s natural R-value, corrosion-resistance, longevity and sustainability contributed to the efficient and economical operation of their stills.

aquatherm PP-R piping fits the bill for insulation and sustainability requirements

aquatherm PP-R piping fits the bill for insulation and sustainability requirements

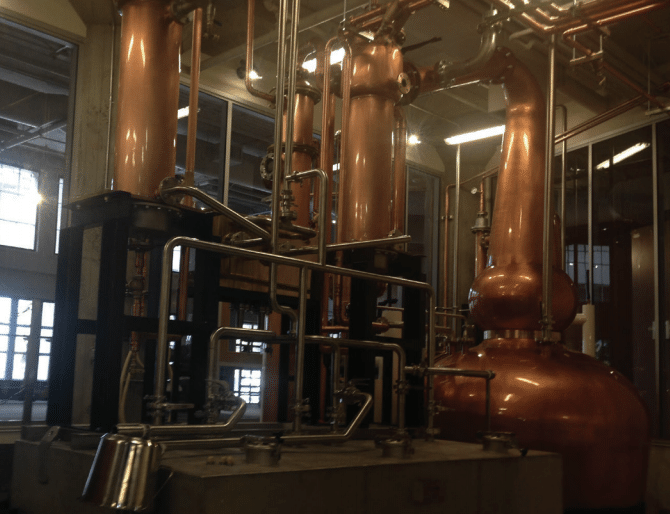

Walk into the Copperworks Distilling Company located in the heart of Seattle’s waterfront, and you’ll be in awe – not only at the gorgeous custom-made copper pot and column stills but at the extraordinary contrast of tradition vs. innovation. The centerpiece of the distillery is its family of four classic copper stills, which were hammered by expert coppersmiths in the highlands of Scotland at Forsyths, one of the world’s leading distilling-equipment manufacturers that has existed in some form since the 1890s.

Additionally, Copperworks’ tasting room highlights a 120-year-old antique oak back bar originally handmade in Montana. Juxtapose that image with the distillery’s modern take on sustainability: The company is dedicated to minimizing water usage, energy consumption and waste production throughout its operations. For example, the stills are heated by energy produced from biomass, a renewable non-fossil fuel source – basically clean waste wood –that doesn’t add carbon to the atmosphere.

The craft distillery focuses on all-malt products; it currently is producing gin and vodka while its whiskey is aging in charred new American oak barrels. Although Copperworks has been in the planning stages for about four years, construction on the 6,974-sq-ft space, which includes a 1,700-sq-ft retail area, began in early 2013. The project was completed in August 2013, and the distillery opened to the public in October 2013, offering tastings, tours, classes, and other events focused on enjoying and learning about fine distilled spirits.

According to Jason Parker, co-owner and distiller along with Micah Nutt, the distillery currently is producing approximately 2,000 cases per year, which he expects to increase by about 1,000 to 2,000 cases annually. Although Parker and Nutt have plans to eventually escalate production, they do not anticipate a move anytime soon, if ever.

“When we built this place, we built it to be the final factory that we will need, instead of just building it to be replaced when we grow larger,” Parker said. “It’s capable of producing the maximum allowable by Washington State per year, so we can be in business forever without having to change our facility or our recipes. Increasing the size of the equipment means you have to change your process to achieve the same taste.”

SEARCHING FOR AN EFFICIENT SOLUTION

Parker and Nutt begin their distilling process by making a 100% malted-barley beer in three stainless-steel fermenting tanks. The beer then is put into one of four copper stills, the size of which depends on what kind of alcohol is being made. The largest, a 3-ton, 15-ft-tall pot or “wash” still, can produce up to two 53-gal barrels of whiskey per day; the next pot or “spirit” still also is used for whiskey production.

Parker and Nutt begin their distilling process by making a 100% malted-barley beer in three stainless-steel fermenting tanks. The beer then is put into one of four copper stills, the size of which depends on what kind of alcohol is being made. The largest, a 3-ton, 15-ft-tall pot or “wash” still, can produce up to two 53-gal barrels of whiskey per day; the next pot or “spirit” still also is used for whiskey production.

Copperworks’ vodka and the base for its gin come from a 25-plate column still; the final pot still, used only for gin, is the smallest in volume but stands as tall as the others. Once in a still, the beer is heated by steam coils. Because alcohol boils at a lower temperature than water, alcohol vapor rises off of the simmering beer while the water stays behind; this process is called distillation. The alcohol vapor rises to the top of the still, called the swan neck, and then travels down through a shell-and-tube condenser. The condenser features a center of small-diameter copper tubes surrounded by a jacketed shell; inside the shell, cold water runs around the copper tubes, cooling the alcohol vapor and turning it back into a liquid state.

When Parker and Nutt were close to the end of the buildout, they realized that the way Scottish distillers run their stills is purposely inefficient because they use a virtually endless reservoir of river water as a coolant. However, because Copperworks uses the municipal water supply, the co-owners had to devise a way of increasing process-cooling-water efficiency without changing the stills’ design.

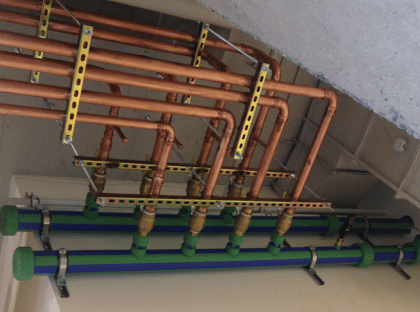

The co-owners decided to install a stainless-steel 500-gal Evapco cooling tower on the roof of the six-story distillery. Cold water is piped from the cooling tower down to the condenser on the ground floor; the water flows into the bottom of the condenser and cools the copper tubes. The tubes, in turn, warm the water; the hot water and resulting steam rise to the top of the condenser and then are piped back up to the cooling tower. Recirculating the same 500 gal of water per batch in a continuous loop means Copperworks is essentially moving about 70,000 gal of water per day.

MAKING THE SWITCH

Parker and Nutt originally installed copper piping as the circulation system to and from the cooling tower and condenser, a move Parker now deems “premature.” The co-owners quickly realized the copper piping was not well insulated and could not keep the process cooling water appropriately chilled.

Parker and Nutt originally installed copper piping as the circulation system to and from the cooling tower and condenser, a move Parker now deems “premature.” The co-owners quickly realized the copper piping was not well insulated and could not keep the process cooling water appropriately chilled.

Parker turned to Greg Leaver, president of Clearview Mechanical Inc. in Seattle, to help solve the problem. Leaver believed he had the answer with aquatherm polypropylene-random (PP-R) piping systems.

“I had worked with a number of engineers who had suggested [aquatherm piping] as a potable solution, but I thought it would work for this project,” Leaver said. “aquatherm has an inherent R-value, doesn’t experience corrosion, is designed for a 60-year life and is very green. These guys are also very conscious of the environment, so it was a win-win situation.”

Clearview had been introduced to aquatherm’s polypropylene-random (PP-R) pipe by the local manufacturer’s representative, Ridgeline Mechanical Sales. Ridgeline, which has offices throughout the Northwest and a reputation for detailed product knowledge and support, provided extensive details about the heat-fused, highly engineered pipe.

Parker and Nutt chose aquatherm’s blue®, a lightweight, environmentally friendly piping system specifically engineered for hydronic, geothermal and industrial applications. blue is engineered to be a superior alternative to CPVC, galvanized and even stainless steel. aquatherm’s PP-R piping is hydrophobic, meaning it repels water from its surface; this protects the pipe wall from eroding and leaking. The smooth, chemically inert material prevents scaling and corrosion buildup, so the performance of the pipe never suffers, even without chemical treatment. The piping offers longevity and ongoing performance without weakening over time. Additionally, aquatherm’s faser-composite technology reduces linear expansion and contraction by about 75% and improves impact resistance.

“I considered other plastics and galvanized steel,” Leaver said. “But aquatherm is a superior product. We have used PVC in other projects for condenser water, but it’s not a very clean product, it’s not easily recycled in the future and I don’t think it would have as long a life. The steel pipe is good, but not as smooth. It wouldn’t have the same life and it’s certainly not as green.”

Although Parker estimated that aquatherm piping was approximately 10% more affordable than other options for this project, the Copperworks co-owners were even more impressed with the piping’s thermal insulation capabilities as well as its green factor. The piping has a low thermal conductivity that amounts to an R-value of about 1.4 per inch of pipe wall. aquatherm’s natural R-value improves uninsulated energy performance in areas where insulation is difficult to install and can reduce the amount of insulation needed to meet current energy codes.

Further, aquatherm’s pipes are non-leaching and fully recyclable. aquatherm adheres to the strictest production standards for sustainability, using the lowest-impact manufacturing processes available. PP-R piping is relatively clean to make, requiring only two steps of refinement, and only 3% of total petroleum is used for plastics production, giving it a much lower impact than the mining and smelting operations used to create metals.

aquatherm piping’s green attributes were music to the Copperworks co-owners’ ears. “We’re dedicated to being good stewards with our resources,” Parker said. “We have an opportunity to make an impact as a new business, so we wanted to focus on sustainability from day one.”

HEAT FUSION KEEPS SYSTEM IN PLACE

Once the copper piping was removed, five Clearview Mechanical employees were trained on aquatherm’s unique heat-fusion welding process. aquatherm PP-R piping uses reliable heat fusion to form connections. Heat fusion bonds both sides of a joint into a single, homogenous material without the use of chemicals or mechanical connections, which eliminates systematic weaknesses and fail-points in the pipe. The seamless heat-fusion connections, combined with the piping’s resistance to corrosion and abrasion, help to ease leakage concerns.

Once the copper piping was removed, five Clearview Mechanical employees were trained on aquatherm’s unique heat-fusion welding process. aquatherm PP-R piping uses reliable heat fusion to form connections. Heat fusion bonds both sides of a joint into a single, homogenous material without the use of chemicals or mechanical connections, which eliminates systematic weaknesses and fail-points in the pipe. The seamless heat-fusion connections, combined with the piping’s resistance to corrosion and abrasion, help to ease leakage concerns.

Two to three workers were able to install 320 ft of 4-in. blue with rented Widos welding equipment. Some 2- and 1-in. piping also was used for instrument ports and bypass valves.

“The job looks very good,” Leaver said. “There definitely was a learning curve for us to learn how to use it, but we would use it again in both process and domestic water piping applications.”

In the end, Copperworks was outfitted with a PP-R piping system that suited its requirements exactly. Now, Parker and Nutt have precisely what they needed: an efficient, secure and sustainable method to pipe thousands of gallons of process cooling water up and down a six-story building.