HIGH IN THE ROCKIES, AQUATHERM PIPE HELPS “BUGS” DO THEIR WORK AT PALLADIUM MINE

The flexibility that aquatherm offered and its quick installation time resulted in such a positive experience that the mine is considering it for other projects.

The Challenge

Mine staff required a quickly installed and long-lasting aeration grid for wastewater treatment in a demanding environment.

The Solution

The flexibility that aquatherm offered and its quick installation time resulted in such a positive experience that the mine is considering it for other projects.

Stillwater Mining Company is engaged in the development, extraction, processing, smelting, refining and marketing of palladium, platinum and associated metals from a geological formation in southern Montana known as the J-M Reef. Stillwater, which employs 1,600 people, is the only U.S. producer of palladium (used in making catalytic converters and in aerospace applications) and platinum (used in jewelry and other applications), and its Stillwater Mine has been operational since 1986.

The management team behind Stillwater Mining Company (SMC) has earned a solid reputation and received awards for exceeding regulatory requirements and seeking out new technologies and innovative processes to address environmental issues. The Stillwater Mine operations extend laterally approximately six miles east to west and vertically more than one mile at elevations of 2,000 to 7,500 feet above sea level. The J-M Reef is accessed by a 1,950-foot vertical shaft, ramps and declines.

AS ENVIRONMENTALLY FRIENDLY AS POSSIBLE

Josh Harris, Stillwater’s Environmental Compliance Specialist, explained that he and his team are constantly seeking innovative technologies and working to keep the mine on the leading-edge of environmental advancements. For example, Stillwater was one of the first mining companies in the U.S. to use the nitrification process (known at SMC as the “bug plant”) to treat mine water and remove ammonia from their water stream.

Stillwater has utilized a moving bed bio-reactor (MBBR) for the de-nitrification of mine water since 1996. This process employs “cells” or basins to provide the required retention time to effectively treat mine water. Untreated mine water is pumped from a lined storage pond to the uppermost treatment cell where it passes through plastic media housing bacteria.

Mine water is gravity fed through a series of six nitrification/denitrification cells. This process enables total nitrogen removal in a compact space through high-density nitrifying and denitrifying bacteria populations. The bacteria create a biofilm that clings to the surface area of the media which effectively nitrifies mine water to treat ammonia (when supplied with dissolved oxygen) or denitrifies mine water when supplied with a carbon source. Dissolved oxygen for nitrification is achieved through the use of high-volume blowers and an underwater aeration grid at the bottom of the cell.

Harris was in the process of designing the nitrification system in late 2013 and decided, with his design team, to split the uppermost 137,368-gal cell (cell-5) into two nitrification cells (they would be renamed: #5A and #5B). The existing cell was 68 ft by 30 ft by 10 ft deep. A 10-ft tall concrete wall would be erected in the center, dividing the basin into two 68,500-gal capacity cells.

OPEN TO ALTERNATIVE PIPING MATERIALS

As the team was designing the aeration grids, which were to measure 30 ft by 22 ft, using 6-in. pipe mains and 1 ½-in. branches, Harris recalled a conversation with MDM Supply Company’s Bob Gaughen. MDM is a division of Dakota Supply Group and a full-line wholesale plumbing, heating and industrial PVF supply house with full service locations in Billings, Helena, Kalispell, Bozeman, and Missoula. Gaughen had mentioned aquatherm polypropylene-random (PP-R) piping systems to Harris as something to consider for future projects. MDM focuses on solutions, and Gaughen recognized an opportunity to solve a problem at Stillwater.

Located at roughly 5,200 feet above sea level, in a very remote area prone to extreme temperatures, the aeration grids would also be exposed to a corrosive environment. Since the mining operation makes extensive use of high-density polyethylene (HDPE), the team was familiar and comfortable with the heat fusion process. Heat fusion permanently joins a pipe and fitting at the molecular level using pressure at high heat. This is the same connection method used to connect aquatherm piping systems.

“We have used a lot of HDPE and it holds up pretty well. Since this installation was going to be outside and underwater in a somewhat corrosive environment, we were open to considering some alternatives,” said Harris. Gaughen explained that aquatherm pipe doesn’t expand and contract as much as many other pipe systems, and because it is hydrophobic and chemically inert; it resists scaling and “getting fouled up.”

Harris and his team, which also included Kestrel Engineering Group (Billings, MT), investigated aquatherm and learned that the German-made piping systems have been around for four decades and used in over 70 countries. Local aquatherm manufacturer’s rep, Ridgeline Mechanical Sales, with offices throughout the Northwest and a reputation for detailed product knowledge and support, also helped out with the education and training process.

“The aquatherm specs looked good and the drill and tap [fusion outlets] that aquatherm offers versus having to create custom pieces with HDPE, was a big selling point for me. Just the flexibility and all of the different fittings and connections were really big points for us on this project,” Harris recalled.

FUSION OUTLETS AND AN EXPERIENCED INSTALLER: ESSENTIAL

aquatherm offers over 400 valves and fittings and its fusion outlets offer considerable time and material savings. The fusion outlets really shine in main/branch applications since they allow branch lines to be installed when the pipe is already in place. The pipe is simply drilled into with a bit that removes the PP-R material and the fusion outlet is welded into the drilled hole. The hole can be made in the side wall of the pipe anywhere on the pipe that is accessible.

Once the design team selected aquatherm, Harris consulted with Gaughen to bring an experienced aquatherm contractor to the field. Gaughen had a ready answer: Harvey’s Plumbing & Heating. Established in the Bozeman area for the past 25 years, Harvey’s provides superior service with the most economical and energy efficient equipment available, and the company has done several large aquatherm installations.

Harris explained that experience with heat fusing PP-R was essential. “Their experience with aquatherm was huge. I’d seen the catalog and done some research, but their comfort with the product was so important that I made a sole-source justification to ensure Harvey’s would be doing our install,” Harris added.

“The easy fabrication aspect of aquatherm and the numerous connections available for it were real keys. Being able to prefab all of the fusion points for all the connections and bring it onsite for a quick and easy installation is a major feature because I can’t afford to have the system down for very long,” Harris said.

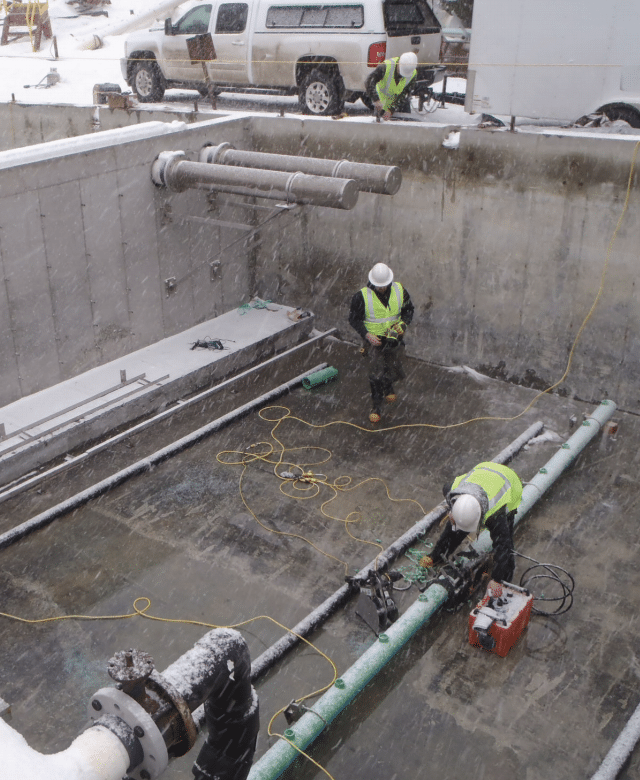

FABRICATION SAVES TIME IN WINTERY CONDITIONS

With a short window to perform the installation, the Harvey’s team, led by Ron Huber, heating division supervisor, began by prefabricating a large portion of the job in their shop. Owner Bob Harvey explained that the ability to socket fuse and insert outlets wherever needed was a huge benefit on this project, and other aquatherm jobs they’ve done. “Being able to create manifolds and takeoffs in straight lengths is huge on a job like this, and plus the flow rate is way better than PEX and copper,” Harvey said.

“We saved a ton of time on this job because we were able to prefab,” Harvey added. “We fabbed the mains with outlets placed on them and capped them up. It was roughly 150 hours of shop time and maybe 50 hours on the jobsite.”

Harris and his staff were impressed with the speed of the installation despite some adverse weather that included snow. “The installation went super smooth. We had such a limited window to get it in. We designed it, got the plans to Harvey’s, and they prefabbed it. Then it was just a matter of making those fusions. Both sides went in in one full day,” he said.

According to Gaughen, using stainless steel would have been expensive and there would have been a lot of tees. Plus the stainless steel would not have withstood the sulfur dioxide, and hand drilling 1,148 holes in the metal would have been extremely difficult and time consuming. Harvey added, “Even with HDPE, you couldn’t have done the fusion outlets and that would have meant more labor.”

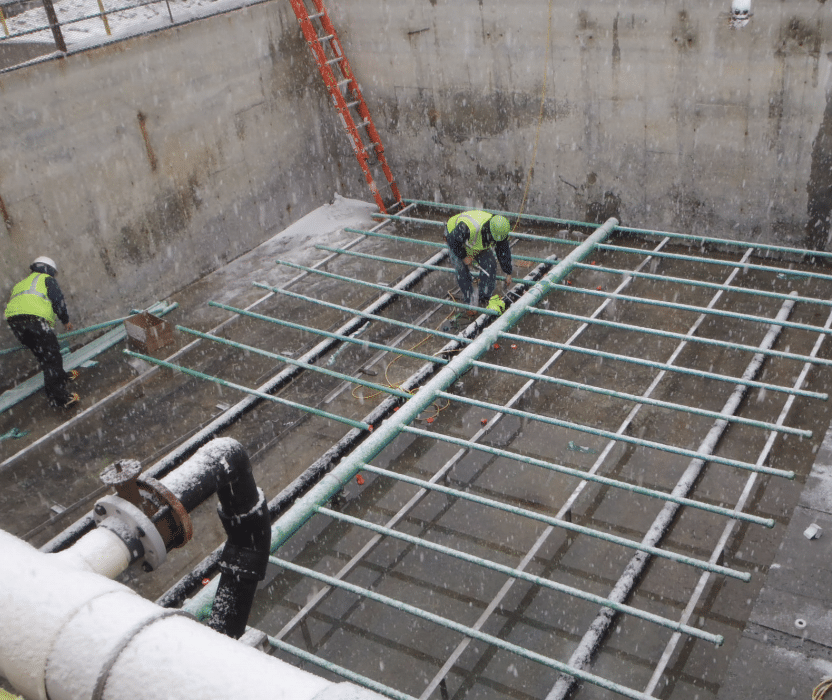

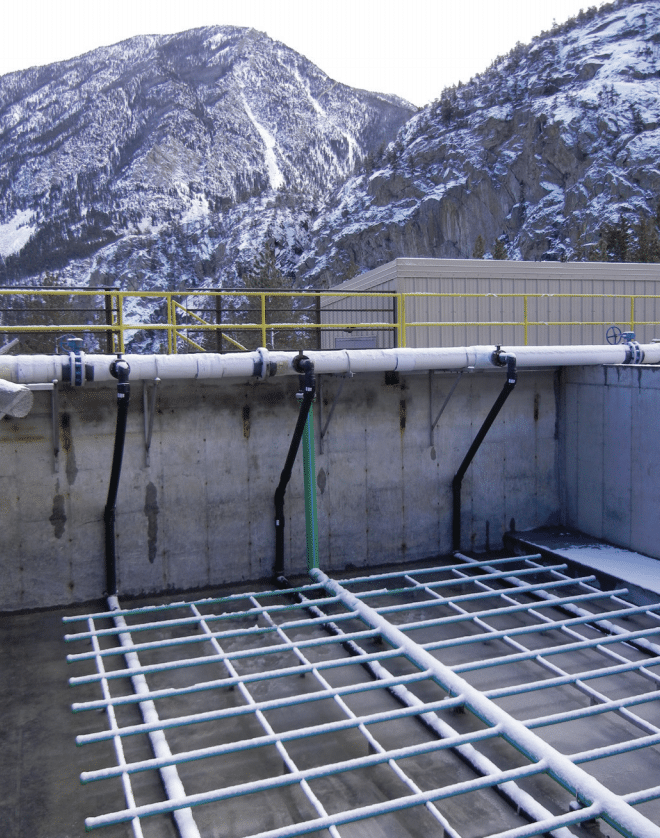

The installation was completed in January 2014 and passed a full pressure test, but the bacteria-housing media has not been introduced yet. When the media is introduced, two Kaeser ES291C blowers located in a nearby mechanical room will provide 574 cfm per basin through the aeration grid made from aquatherm.

A total of 575 3/16-in. holes were drilled throughout the system laterals, providing an equal distribution of 1 cfm per hole in each basin. The Kaeser blowers are connected stillwater flanges to 6-in. aquatherm pipe and a series of valves controlling air supply to the aeration grid 10 ft below on the basin floor. The grid is suspended on a stainless steel bracket system a foot above the cell floor.

In the end, Harris said the aquatherm pipe has already proven its worth at the mine site and is considering using aquatherm for other water treatment options. He also noted that an added benefit is the environmental friendliness of PP-R. aquatherm is fully recyclable, rust- and corrosion-free and long-lasting, and the polypropylene material used to make it requires less energy for initial production than other piping materials. Additionally, PP-R is nontoxic and is a byproduct of petroleum processing.

“I like that it can be pre-fabricated to fit within our existing influent and effluent systems while its weight versus steel offers easier maneuverability and installation into a pre-existing space,” Harris said. With the cells ready to go online and more aquatherm potentially being installed on the site, the project was clearly successful.

“I don’t think they could have used any other type of pipe and created this system as designed,” concluded Gaughen.