PIPING ALTERNATIVE PROVIDES EXTENSIVE SAVINGS AND HELPS FORT HOOD “GO GREEN”

aquatherm Climatherm cost approximately 20% less than steel and copper and contributed to the project earning LEED points

The Challenge

Base officials sought a less expensive, more environmentally friendly HVAC piping option

The Solution

aquatherm Climatherm cost approximately 20% less than steel and copper and contributed to the project earning LEED points

Located in central Texas, Fort Hood is the only post in the United States capable of stationing and training two U.S. Army Armored Divisions. The 340-square-mile installation is home to more than 52,000 currently assigned soldiers and 100,000 family members.

With an estimated economic impact in 2008 of $10.9 billion statewide, the installation is also the largest single-location employer in Texas. So when the Army’s Department of Public Works (DPW) was considering its HVAC piping options for several new Fort Hood construction projects, a cost saving and environmentally friendly piping alternative was very appealing.

Thus, the fact that aquatherm Inc.’s polypropylene-random (PP-R) piping would be able to come in at roughly 20% less than copper or steel while also contributing to several USGBC LEED points made it very compelling. The German-manufactured pipe has been one of the world’s greenest piping systems for nearly 40 years and proven successful in 70-plus countries. aquatherm also produces the most environmentally friendly piping option available.

Thus, the fact that aquatherm Inc.’s polypropylene-random (PP-R) piping would be able to come in at roughly 20% less than copper or steel while also contributing to several USGBC LEED points made it very compelling. The German-manufactured pipe has been one of the world’s greenest piping systems for nearly 40 years and proven successful in 70-plus countries. aquatherm also produces the most environmentally friendly piping option available.

The fusion process is fundamental to polypropylene’s ecofriendliness. Simply putting a piece of pipe and a fitting on opposite ends of an aquatherm welding iron for a specified time (about 24 seconds for two-inch pipe), and then joining them together creates an incredibly strong connection.

AN INTRIGUING ALTERNATIVE

Lou Castillo, project manager for the DPW, was intrigued when he was presented with PP-R by aquatherm distributor, David Wheeler, of ProLine Marketing in San Antonio. He was, however, “a bit skeptical” about replacing metal with PP-R.”

“We were a little concerned, but once we read more about it, we decided to go ahead and give it a try. We liked the way it was easy to run and took less time for labor, and it really looked cleaner on the design when we installed it,” Castillo said.

After plenty of due diligence, the DPW asked Marvin Carter, president and co-owner (along with Scott Hunter) of HVACmasters in Round Rock, TX, to try aquatherm on two Fort Hood HVAC renovations. Carter, with 35 years of industry experience – including 15 years at Fort Hood – was also a bit hesitant.

“We all had reservations with the product at first. As you know change is not easy for employees or companies that have predominantly used other products for years,” Carter recalled. However, Carter agreed to try aquatherm. The product is distributed in the U.S. and Canada by aquatherm, Inc., and was approved for use on these projects due to its environmental friendliness and since all new projects allow a certain percentage of items to be manufactured outside the U.S.

The trial installation was to take place on two “five-company buildings” that were originally built in 1983 and 1984. The 25,000-square-foot, one-story structures are used for the administration and supply of an entire company. Neither had air conditioning in the supply room and both had substandard air conditioning in the administration areas.

The goal of the project was upgrading the HVAC systems via new chillers; DDC controls; new, larger AHUs; and replacement of the existing four-pipe system. The piping jobs would traditionally have been specified with standard copper and A-53 steel pipe.

However, Castillo said, aquatherm’s flexibility and durability were critical factors. “Also, not having to use a lot of chemicals in the system and not having to worry about rust in the chilled water systems and the boilers was a benefit,” he added.

ABOUT THE TRANSITION

aquatherm conducted a training session at the HVACmasters shop. Since the HVACmasters technicians were then factory-certified, the installed aquatherm piping has a 10-year warranty on pipe and fittings with a product liability valued at 9 million Euros for personal injury and 4.5 million Euros for property damage per event.

aquatherm conducted a training session at the HVACmasters shop. Since the HVACmasters technicians were then factory-certified, the installed aquatherm piping has a 10-year warranty on pipe and fittings with a product liability valued at 9 million Euros for personal injury and 4.5 million Euros for property damage per event.

HVACmasters’ expertise in pipe fitting helped the staff quickly understand the fusion process. “They actually grasped it pretty fast, but a lot of companies are going to fight it, they don’t want the change. The transition itself is very simple,” Carter added.

HVACmasters purchased the necessary welding irons and jigs to handle aquatherm piping from 1-inch to 3-inch. “It’s a bit costly upfront to get into, but you will save money down the road on labor time,” said Carter.

Carter was quite satisfied with aquatherm’s training and support. “They were knowledgeable with the product and installation, and they also came to the job site and worked with us at the very beginning,” he recalled.

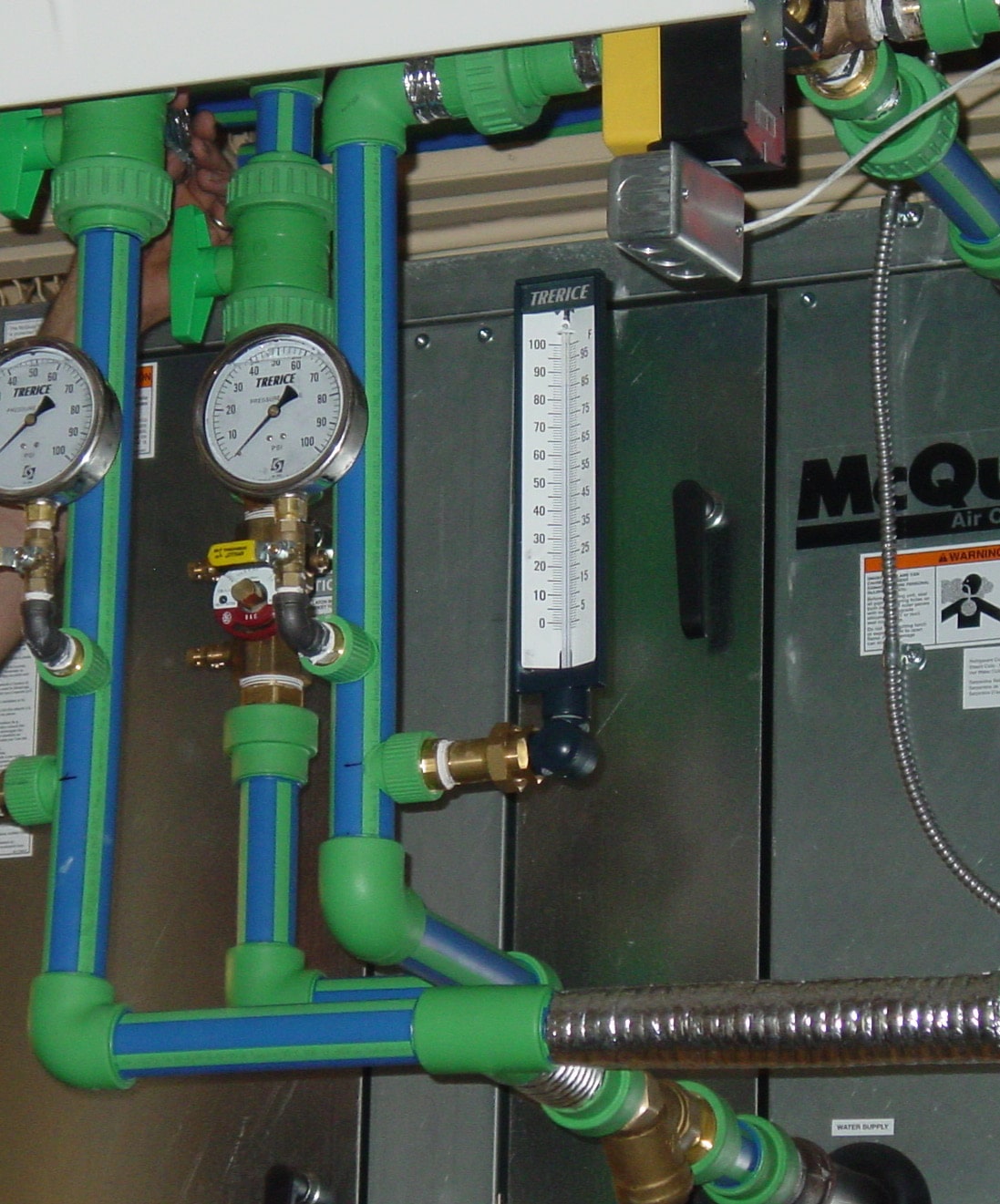

Construction began in January 2009, and was completed in June 2009. aquatherm’s blue, which is designed specifically for HVAC applications, was the specified pipe (the company also makes aquatherm green® for potable water and Lilac for reclaimed water).

Almost 4,000 linear feet of blue piping was installed for chilled and hot water in the buildings. The boiler supply and return lines didn’t need any insulation thanks to PP-R’s natural R-value, providing further savings. The pipes installed on this project range from 1” to 3”.

Overall, the installation proceeded remarkably smoothly. In the thousands of connections made, there were only a couple leaks. Carter said with steel and copper there would have been many more leaks, and added that on a recent job, there were “no leaks, which would have been unheard of with copper or steel.”

THE FUTURE IS FUSION

The five-company building installations were so successful that base officials approved blue for use in a number of other projects and are considering using aquatherm for compressed air and potable water applications. “Now, all the engineers are impressed with the installations and quality of material, and the product is being used throughout several new projects at Fort Hood,” said Carter.

Finally, the Fort Worth Army Corp of Engineers has incorporated aquatherm into its specifications, so that from now on aquatherm can be installed at U.S. Army installations throughout the southern region of the U.S. “Ray Schroeder, the head engineer at Fort Hood and Kelly Mollenkopf, the base’s senior mechanical engineer, who has been instrumental on the job, have both said that aquatherm has a bright future here on the base,” Carter said.