The Challenge

Sport Court needed a state-of-the-art facility with piping that could handle water hammer and wouldn’t get plugged up with lime, scale, and rust.

The Solution

aquatherm pipe was used for chilled water and compressed air applications to cool the large plastic injection-molding machines for many years without worries of failures or future maintenance.

Utah’s Sport Court picks aquatherm PP-R piping for new headquarters facility

When the President of the United States uses your product at the White House, you know the product has struck a chord. Since 1974, Salt Lake City’s Sport Court has designed, manufactured and built nearly 100,000 outdoor basketball courts, indoor gymnasium floors, tennis court surfaces and more across the globe for several sports organizations, including the NBA, NCAA, FIBA and the U.S. Soccer Foundation, as well as at the White House.

With so many fans, Sport Court “has done remarkably well over the last few years, despite the challenging economy,” said Sport Court President and CEO Ron Cerny.

Increasing production capacity by 25% and adding several new 1,000-ton injection-molding machines meant Sport Court needed a state-of-the-art facility with spacious office, manufacturing and warehouse accommodations. The two-story, 170,000-sq-ft project began in June 2013; Sport Court Facility Manager Steve Leake expects the building to be fully functional by January 2014.

OUT WITH THE OLD

The move to a new facility will bring all of Sport Court’s operations under one roof. Even more exciting for Leake, however, was the installation of a new chilled-water system used to cool the large plastic injection-molding machines that manufacture Sport Court’s famous plastic flooring. Over time, the company had experienced a great deal of problems with the old building’s black-pipe system.

“I’m hoping to get rid of the lime, scale and rust that has constantly plagued our factory,” Leake said.

“I’m hoping to get rid of the lime, scale and rust that has constantly plagued our factory,” Leake said.

Leake’s friend Brian Shields, a sales representative for Ritmo, a plastic-piping fusion machine manufacturer, suggested he call Dick Thompson and Carl Pond, sales representatives for aquatherm, a polypropylene-random (PP-R) piping-systems manufacturer, to find a unique option for the industrial application.

“Leake was pretty sold on (aquatherm piping systems) right at the get-go,” Thompson said. “He didn’t want to use anything else. He already was dealing with steel failures at his old facility.”

“I’m trying to cure some of our long-term problems,” Leake said. “With aquatherm, I can get rid of the lime, scale and rust; plus, I don’t have to insulate the pipe.”

Leake had previously tried to fix the issues at Sport Court’s old factory, so he had already considered other types of piping and knew what he didn’t want to install in the new building.

“At our old facility, we were running black pipe, and when we turned off the system, we would have all kinds of scale and rust shake loose, and that would plug all the water lines to the molds,” Leake said. “When we’ve used PVC, it was not able to handle the water hammer, and the glued joints would blow off.”

FINDING A NON-CORROSIVE SOLUTION

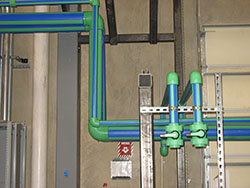

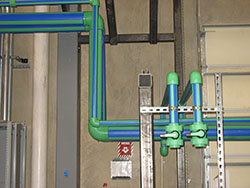

Leake used 1,800 ft of 6-in. aquatherm blue® to route cold water from a 3,000-gal Advantage Engineering chilled-water tank in the mechanical room across the warehouse to the manufacturing center’s long line of injection molding and extrusion equipment. The piping was suspended from the ceiling on steel racking. Another 1,000 ft of 2-in. aquatherm blue was used for chilled water and compressed air for the injection-molding machines and the machine shop. Sport Court’s in-house  maintenance department tied in the 6-in. x 2-in fusion outlets to feed the extruders.

maintenance department tied in the 6-in. x 2-in fusion outlets to feed the extruders.

Long-lasting aquatherm blue is specifically engineered for heating and cooling, industrial, geothermal and compressed-air applications. All of aquatherm’s piping systems are made of PP-R: a simple, chemically stable thermoplastic that is engineered to last for decades. PP-R won’t react with water or most dissolved chemicals, so it is unaffected by corrosion, scaling and erosion – problems that cause the majority of long-term piping failures.

“Black pipe plugs up my water lines with scale, lime and rust. That plugging problem creates hot spots in the mold, and my plastic parts may become deformed. This creates scrap and down time, which is very expensive,” Leake explained.

The old Sport Court facility, which makes up to 15 million parts per year, had to scrap about 1.5-1.7% annually. By installing aquatherm PP-R piping systems, Leake estimates he will be able to decrease that number to or below 1%.

EASE OF USE

A representative from the local aquatherm distributor trained six Sport Court employees and an outside plumber on aquatherm’s exclusive heat-fusion welding process. aquatherm PP-R piping uses reliable heat fusion to form connections; heat fusion bonds both sides of a joint into a single, homogenous material without the use of chemicals or mechanical connections, which eliminates systematic weaknesses and fail-points in the pipe. The seamless heat-fusion connections, combined with the piping’s resistance to corrosion and abrasion, help to eliminate leakage and fouling/plugging concerns.

Leake bought a small set of Ritmo welders for ½- to 2-in. pipes; he also rented a 6-in. Widos butt-fusion machine and a McElroy fusion machine. The distributor’s rep then visited the site to check on the progress of the installation, review tools, and assess the quality of the fusions.

Leake feels not having to use glue, solder or a mechanical connection and gasket gives aquatherm PP-R piping systems an advantage.

“Black pipe has to be laid out and perfectly engineered. It is very difficult to change or replace,” Leake said. “aquatherm is easy; I can fuse outlets in wherever I want. It’s also fairly forgiving: If your weld isn’t perfect, you can bend it and fix the issue. You can’t do that with black pipe; everything has to be perfect.”

Additionally, Leake has been very happy with aquatherm PP-R’s leak-free fusion technology.

“The big plus to aquatherm is that I haven’t had one leak ‒ not one ‒ which I cannot say of anything I’ve ever done with black pipe,” Leake said. “It’s phenomenal; I think aquatherm is going to be the new standard.” In addition to the aquatherm blue, a small amount of 2-in. aquatherm green® was also used to supply the domestic water to office space.

FUTURE SAVINGS

aquatherm PP-R piping systems have a 10-year warranty and are made to last for more than 60 years. The PP-R material also has natural insulation properties, and the systems’ faser-composite layer ‒ which can reduce expansion by 75% ‒ has an R-value of about 1.4 per inch of wall pipe, meaning less insulation is needed to meet current energy codes.

“Twenty years down the road, we won’t have rust problems, and we won’t have to insulate the pipe like we would have [with] steel,” Leake said. “I know that 20 years from now, I’ll see a big savings.”

“I’m hoping to get rid of the lime, scale and rust that has constantly plagued our factory,” Leake said.

“I’m hoping to get rid of the lime, scale and rust that has constantly plagued our factory,” Leake said. maintenance department tied in the 6-in. x 2-in fusion outlets to feed the extruders.

maintenance department tied in the 6-in. x 2-in fusion outlets to feed the extruders.